Perch Lake Lumber CO. Layout Rebuild

Considerable Time and Effort Invested

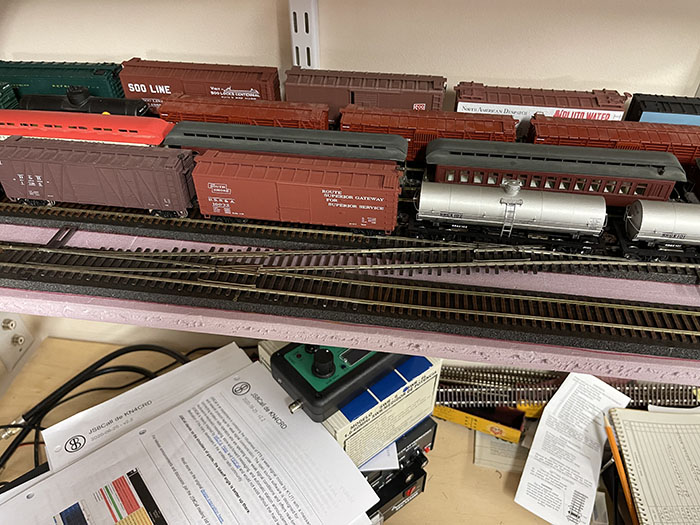

The photographs on this page depict the final hand-crafted turnouts installed on the layout. Observations showed that the transition between rails soldered to PC board ties and adjacent wooden ties adversely impacted operational reliability, primarily due to significant fluctuations in temperature and humidity characteristic of the North Woods.

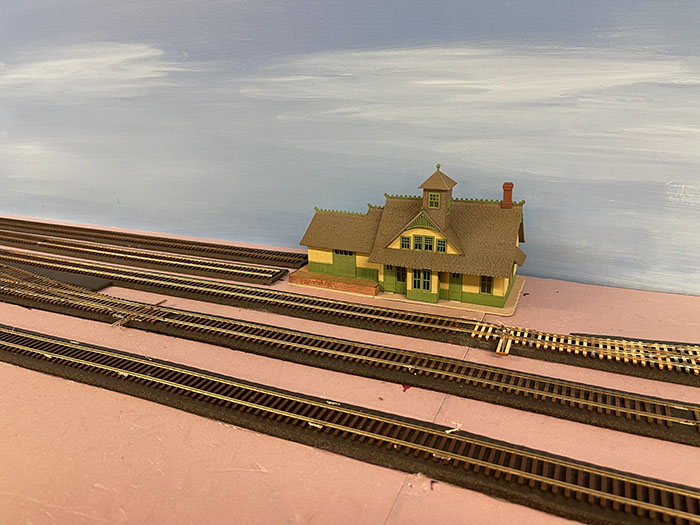

I replaced all hand-made turnouts with 27 Walthers code83 DCC-compatible turnouts to enhance reliability under varying temperature and humidity conditions. Each new turnout required custom fitting into the mainline due to added rail length. Tortoise motors and control wiring now installed on all turnouts, with frog power provided where necessary.

LED indicators have added at each turnout to help operators quickly see switch positions, a feature appreciated by both my club and the SOO Line Historical Society, especially when locomotive engineers cannot easily view the control panels.

The last of the homemade turnouts with wood and PC board ites.

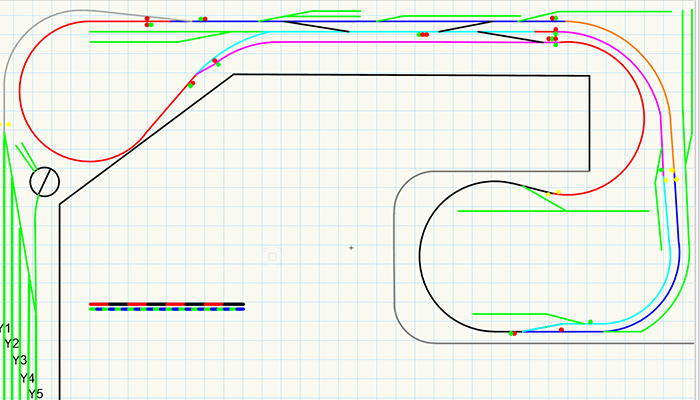

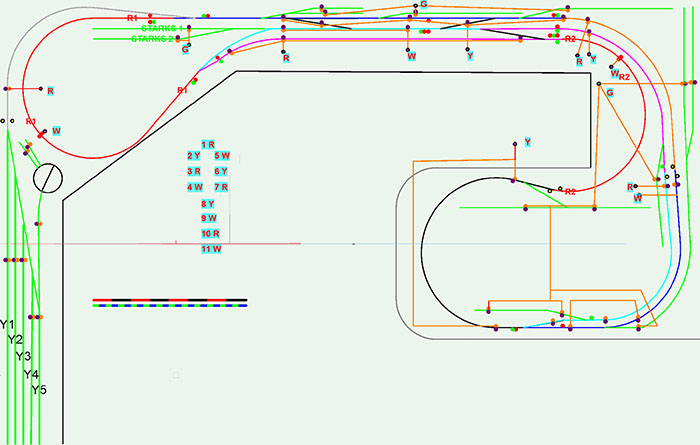

The newest PLLC block drawing uses drop wire colors to mark each block, with a list showing block numbers and their colors.

Starting at block 1 in the staging yard lead, you can trace how blocks function around the layout. Color-coded wires help connect DB20 detectors easily. Signals use red, green, or yellow, sometimes represented by black dots. Of all the turnouts, seventeen operate electronically, while the remainder are ground throws. Green sidings run on dedicated breakers, so shorts do not affect main lines. The mains split between left and right, offering protection without disabling the whole layout.

Signals are planned for the layout.

As of 11/21/25 the blocks are in with BD20 units tested while the layout is operational.

Continued in Section 7, (Click Here)

Return to the start(Click here)

Return to Paul's Workshop (Click here)

Join us in the “Greatest Hobby” as a member of the TLMRC.